Carbon Fiber Skinning is the process of of laying fiber carbon cloth with resin on different objects using them as core for your product. This is commonly used to keep price down when you do not need the extended properties of full layered carbon fiber item.

Usually you will put single layer of carbon fiber cloth and treat it with resins the same way that you would do the top layer of a full carbon item. This is time consuming but relatively easy process to complete in your home workshop. It does not require special tools and is much cheaper than ordering pre-cut fiber carbon sheet designs.

This technique is quite suitable for use of 3D printed items as core. The resulting product especially if skinned on both sides is very close to something you would cut from full carbon plate. As it uses real carbon fiber material and resin it looks like the real thing, feels exactly like it, is quite strong at a fraction of the cost.

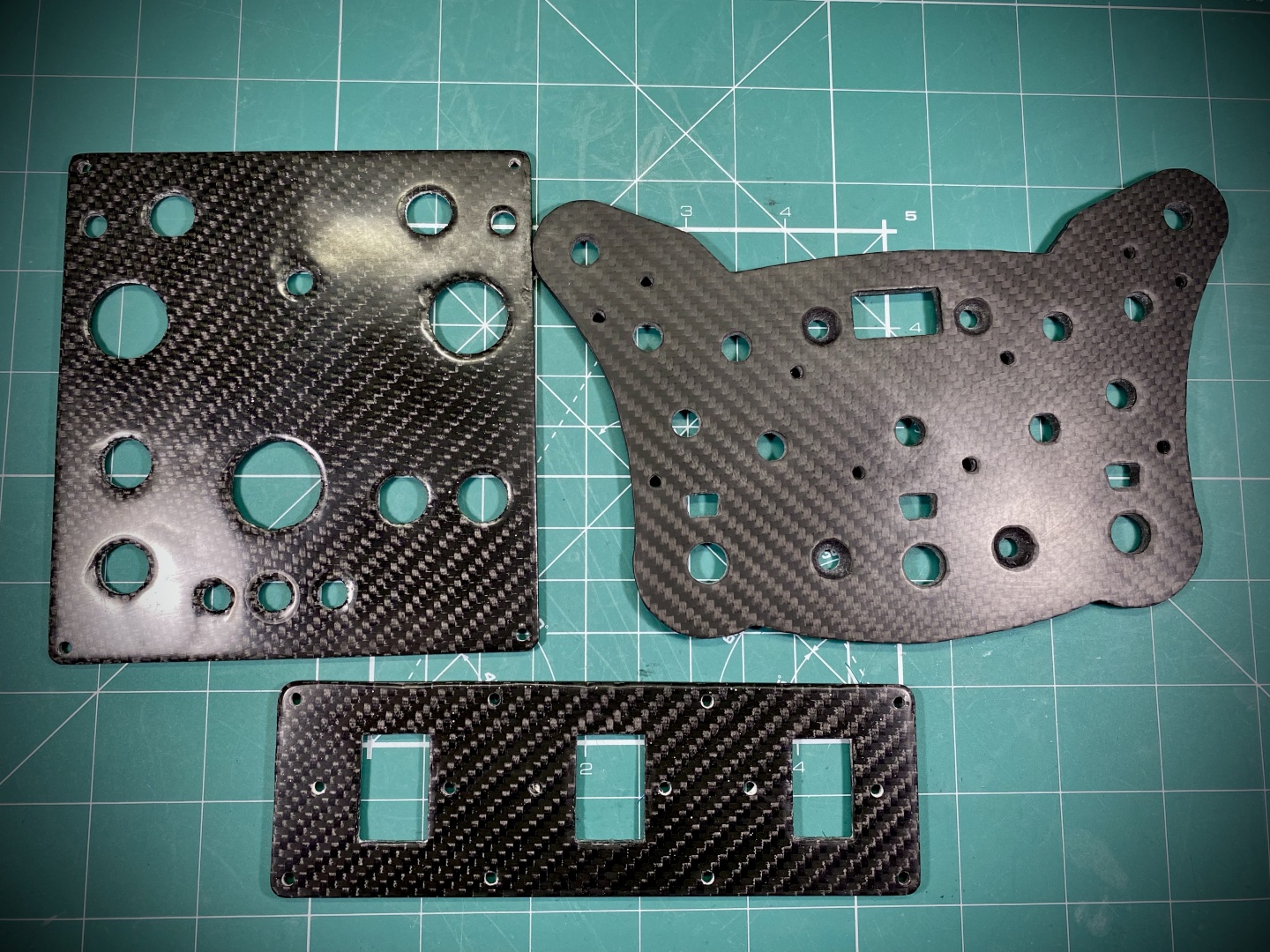

After a lot of attempts and long time perfecting the carbon skinning technique here are some results:

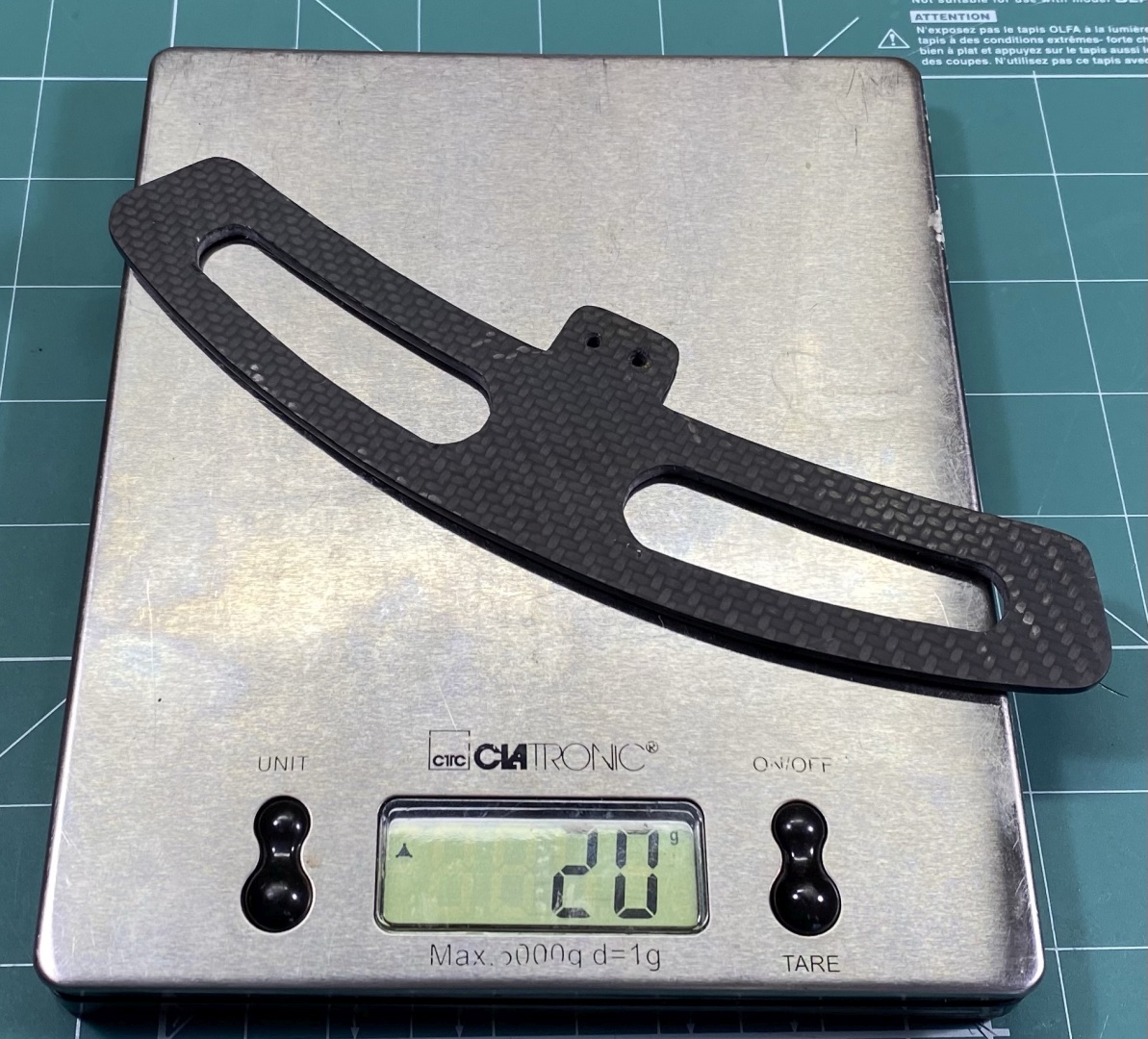

Below is weight comparison between 5mm printed item and 3mm 3D printed core carbon skinned with single layer on both sides. As one carbon fiber layer has heigh between 3.5-4mm I find the 3mm 3D core to be optimal:

As you can see from the above pictures some of the results are far from perfect, but some of them came out quite good. A lot of attempts were made on the processes and here I will present the most successful sequence.

As always you can also check the video guide below:

Carbon fiber is conductive and its dust if inhaled will stay in your lungs. Furthermore it is composed from lots of sharp fibres which tend to go in your skin and are hard to remove. Resin is also toxic. Always wear protective gloves and dust mask, eye protection, work in well aired spaces. Be extra careful when cleaning as well.

Let's start by an overview of the Tools, Materials, Preparation you will need: