Tools Needed

Mostly you will need simple household tools that most probably you already have. This is what I used as follows:

- Sanding block and paper - 180p, 240p, 400p, 600p, 800p, 1200p, 2000p

- Hobby sanding files for the small openings

- Hobby knives for fast resin removal on edges

- Drill with corresponding drill bits to clean holes from resin

- Scissors to cut excess fabric

- Paper masking tape to help you cut the fabric

- 3D Printer Filament Vacuum Bags - help a lot with fabric adhesion

- Eye protection, gloves, respiratory mask

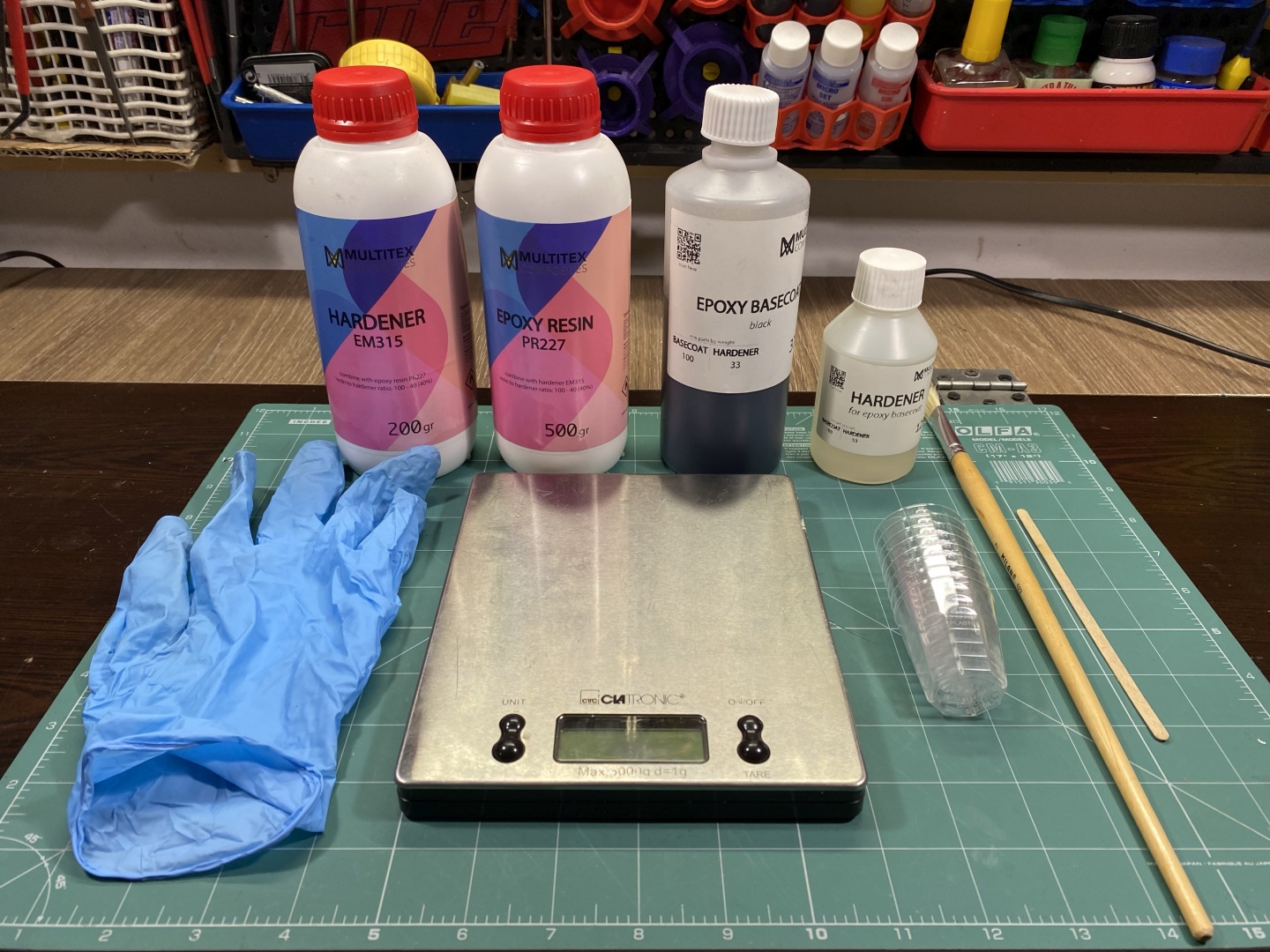

- Kitchen scale to measure resin mix

- Disposable cups and stirrers for resin

Carbon Fiber and Resin

Carbon Fiber Fabric is usually sold by linear meter but you also can buy smaller pieces if you do not need a lot. Base coat is not always needed (it is expensive), you can use resin to stick fabric to item surface but I could not do this successfully with 3D printed PLA. Using base coat is highly advisable.

All prices below are current at the date of writing this material:

- Carbon Fiber Fabric 240gr/m2 - 20x127cm - 8EUR

- Carbon Fiber Fabric 245gr/m2 Twill - price per meter - 36EUR

- Base coat, black 0.5kg - 44EUR

- Crystal Resin 0.7kg - 32.5EUR

- Breather Fabric PES 150 1x1.5m - 2,09EUR/m2

- Peel Ply PA80 1x1.25m - 2,02/m2

Other Tools and Materials

- Clear Coat - depending on preferences you can go with Flat, Gloss, Matt

- Hobby Polishing Paste - again based on preference you have coarse-fine-finish

- The above clear coat also comes in spray, you do not need airbrush

- Hobby Paint Booth is quite helpful for home use, always spray in well ventilated area

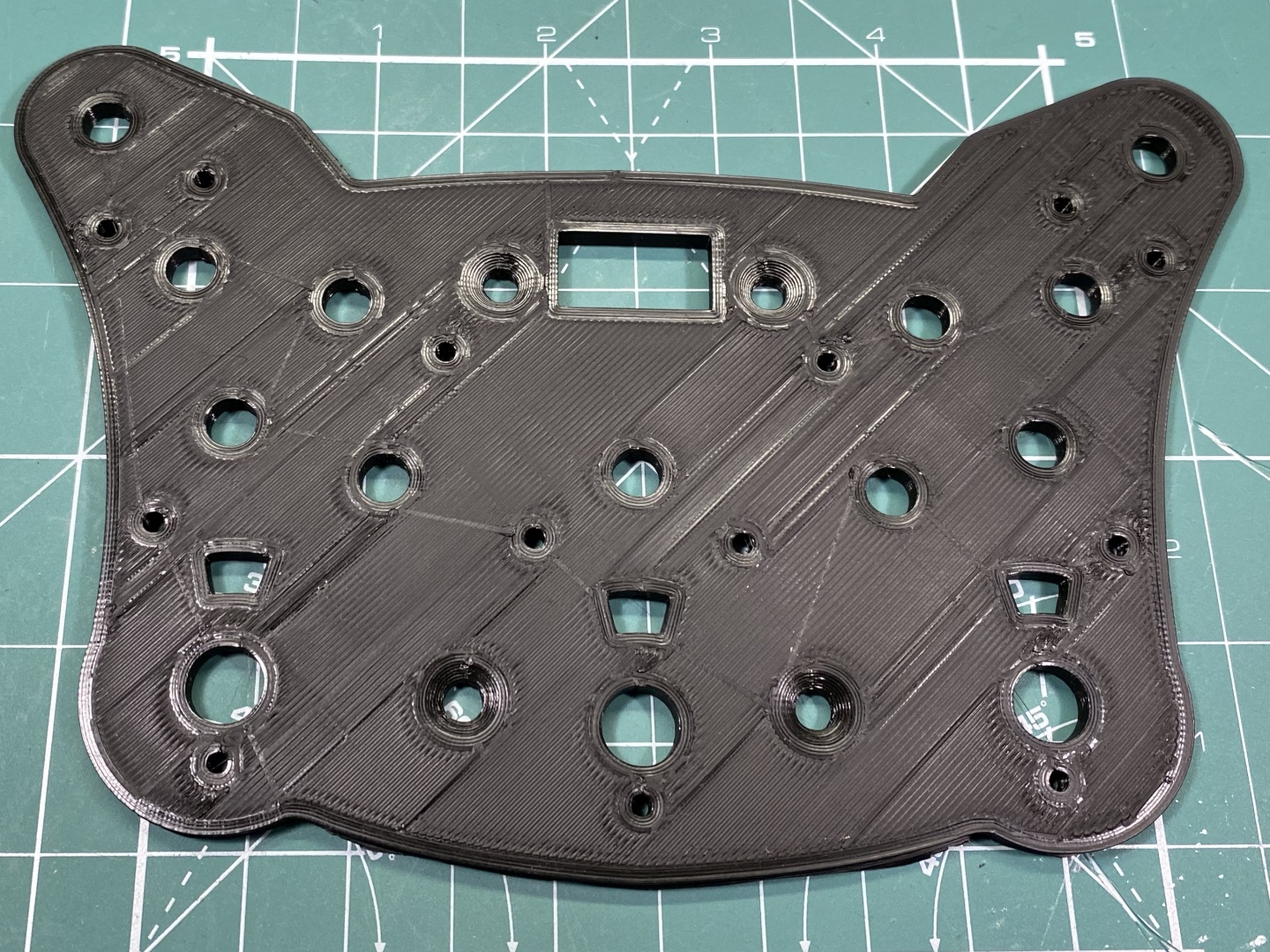

3D printing the Core

First step is just as the title says - print your designs which will be the base core of your product. For double sided skinned items I found 3mm thickness to work well (paddles)and for single sided I opt for 4mm thickness (button boxes, etc.):

Prepare the Surface

To ensure good adhesion surface has to be sanded. Using 180 grit sandpaper dry and wet sand it as much as you can. The surface does not have to be perfectly finished, base coat will fill it in and make it smooth, only needs to be fully roughed up for better contact. After you finish sanding wash with soap water and then rinse thoroughly to remove all dust and oil from the work surface:

At the end the result should be something like below - not perfectly sanded but all surface is fully roughed for better grip:

Next time to start off with the Base Coat: