-

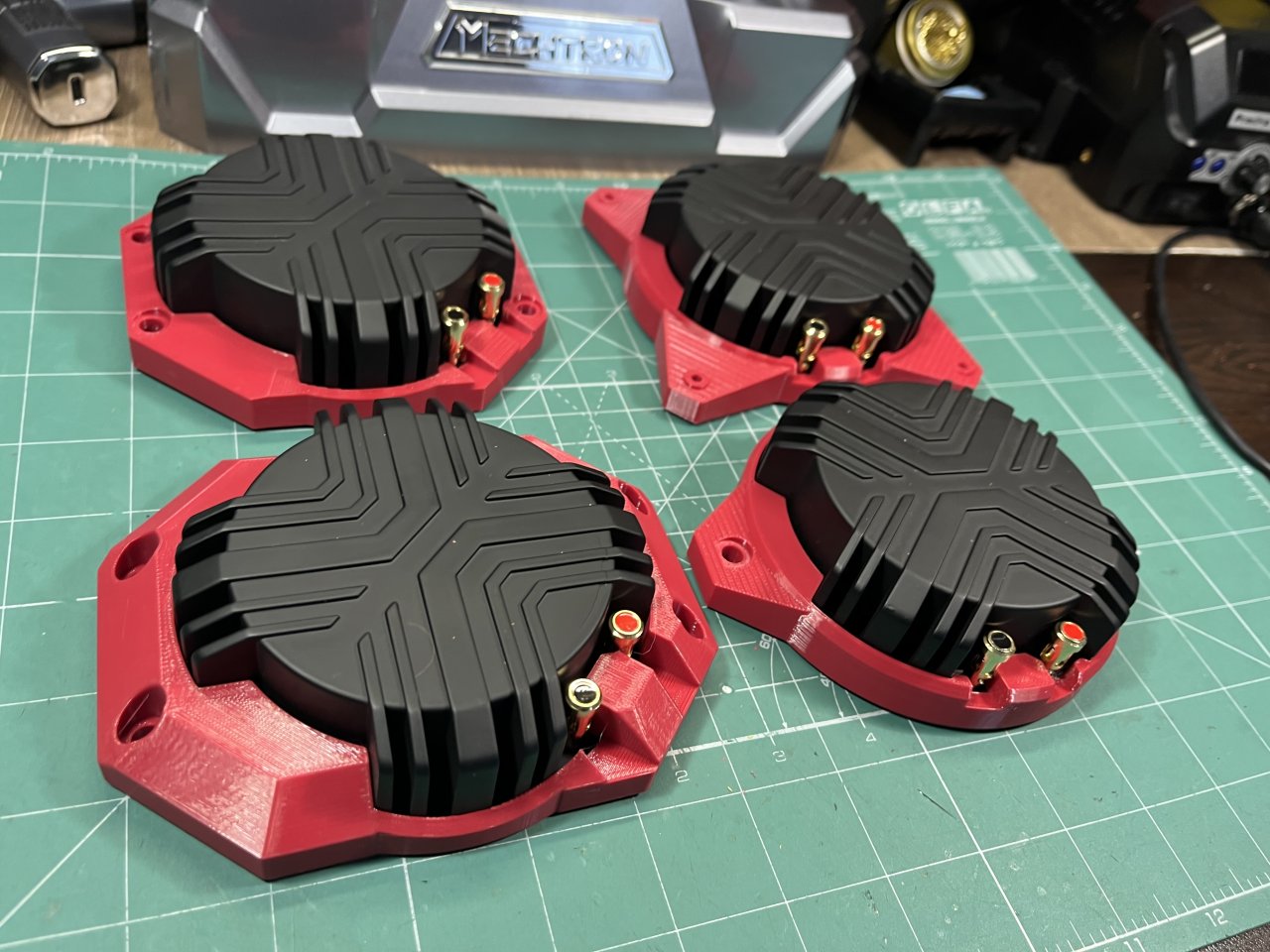

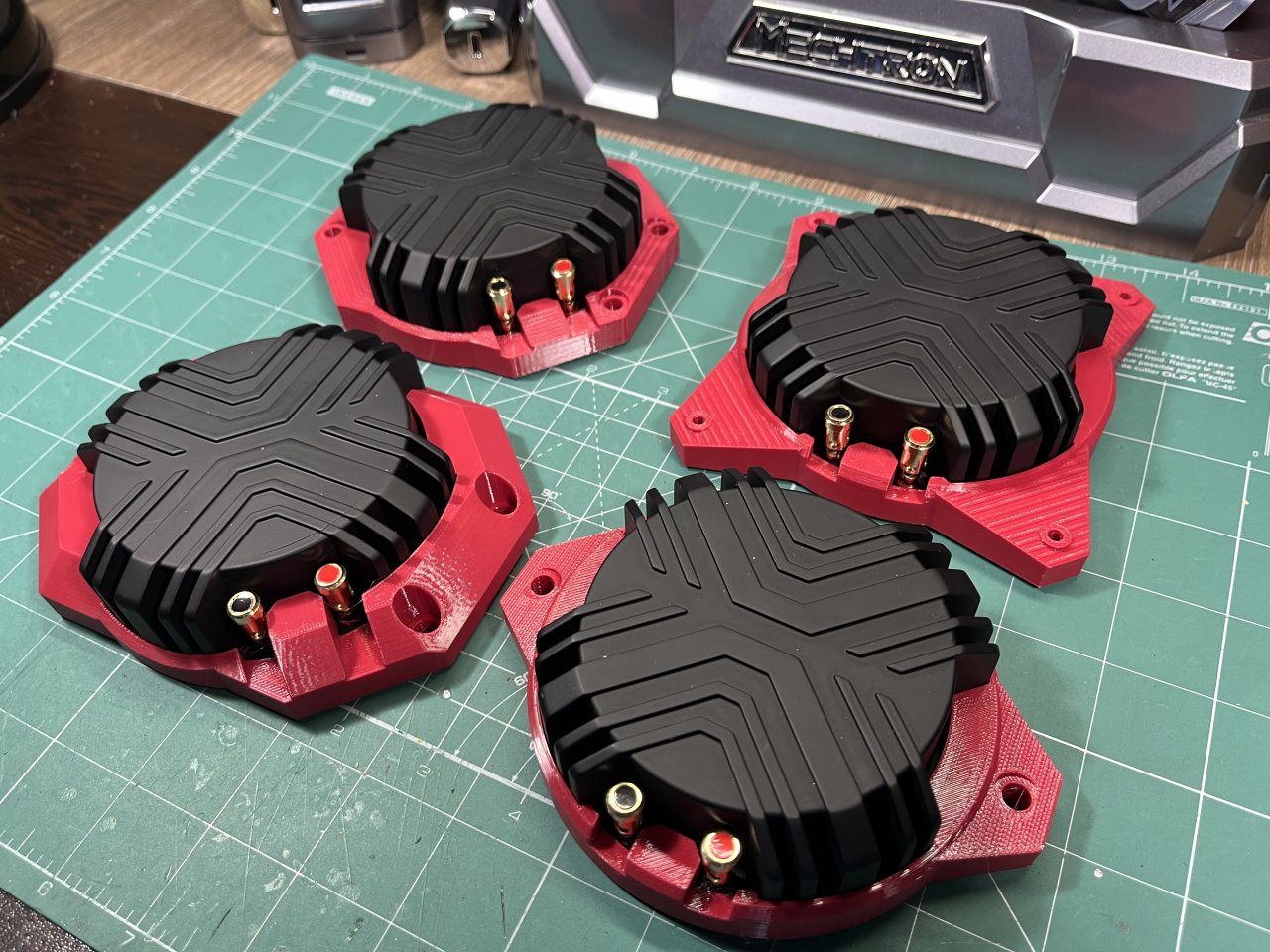

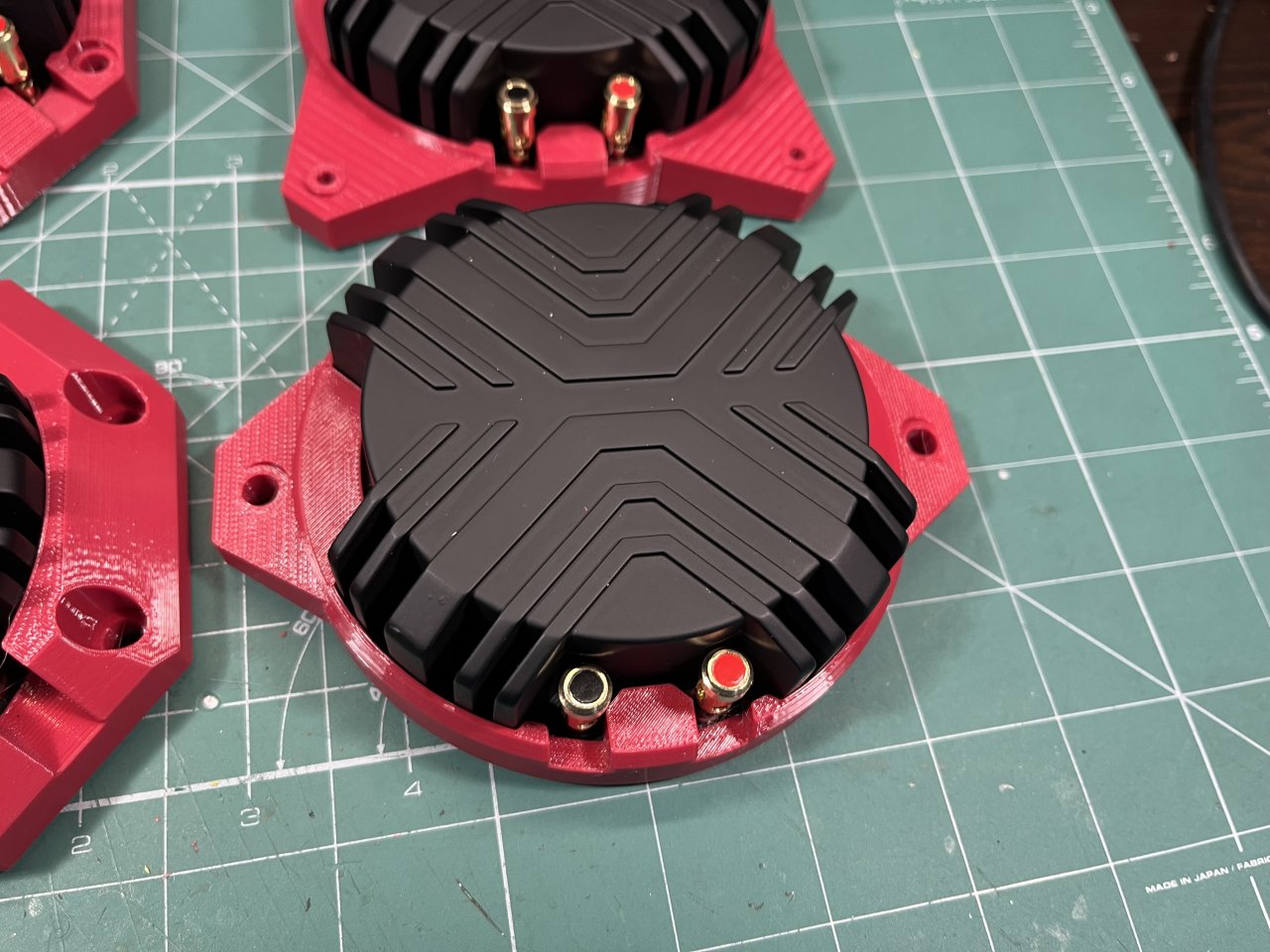

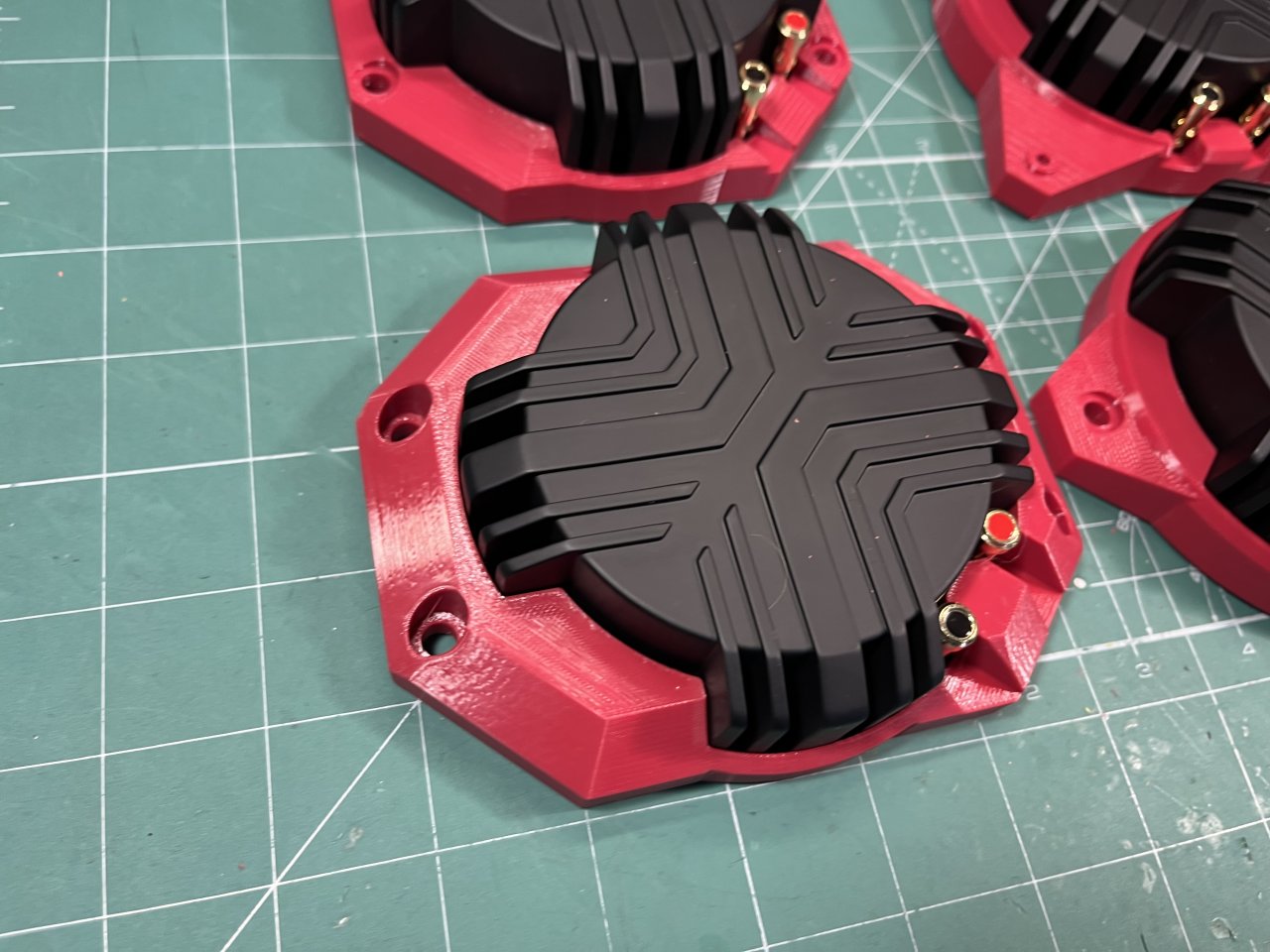

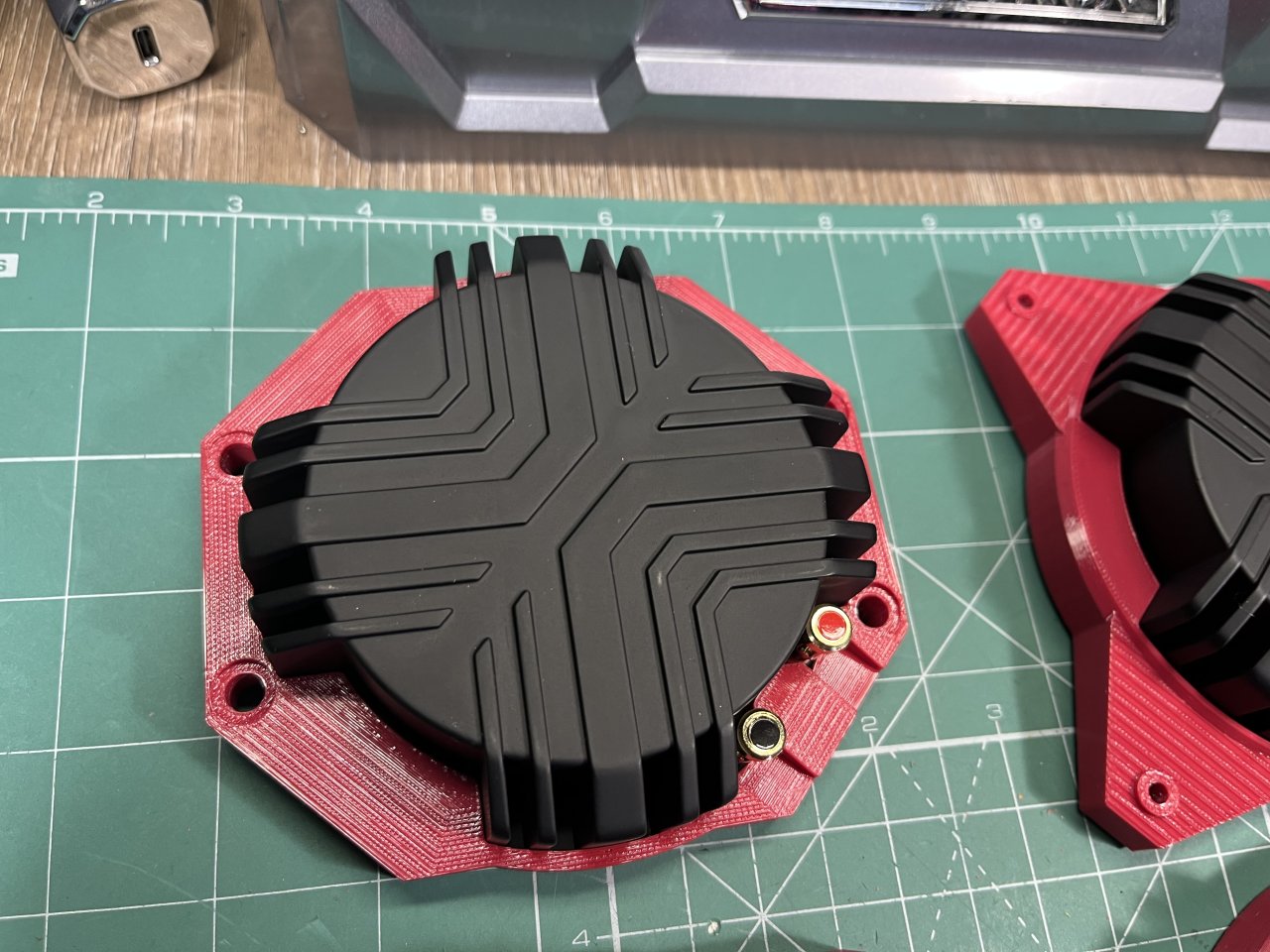

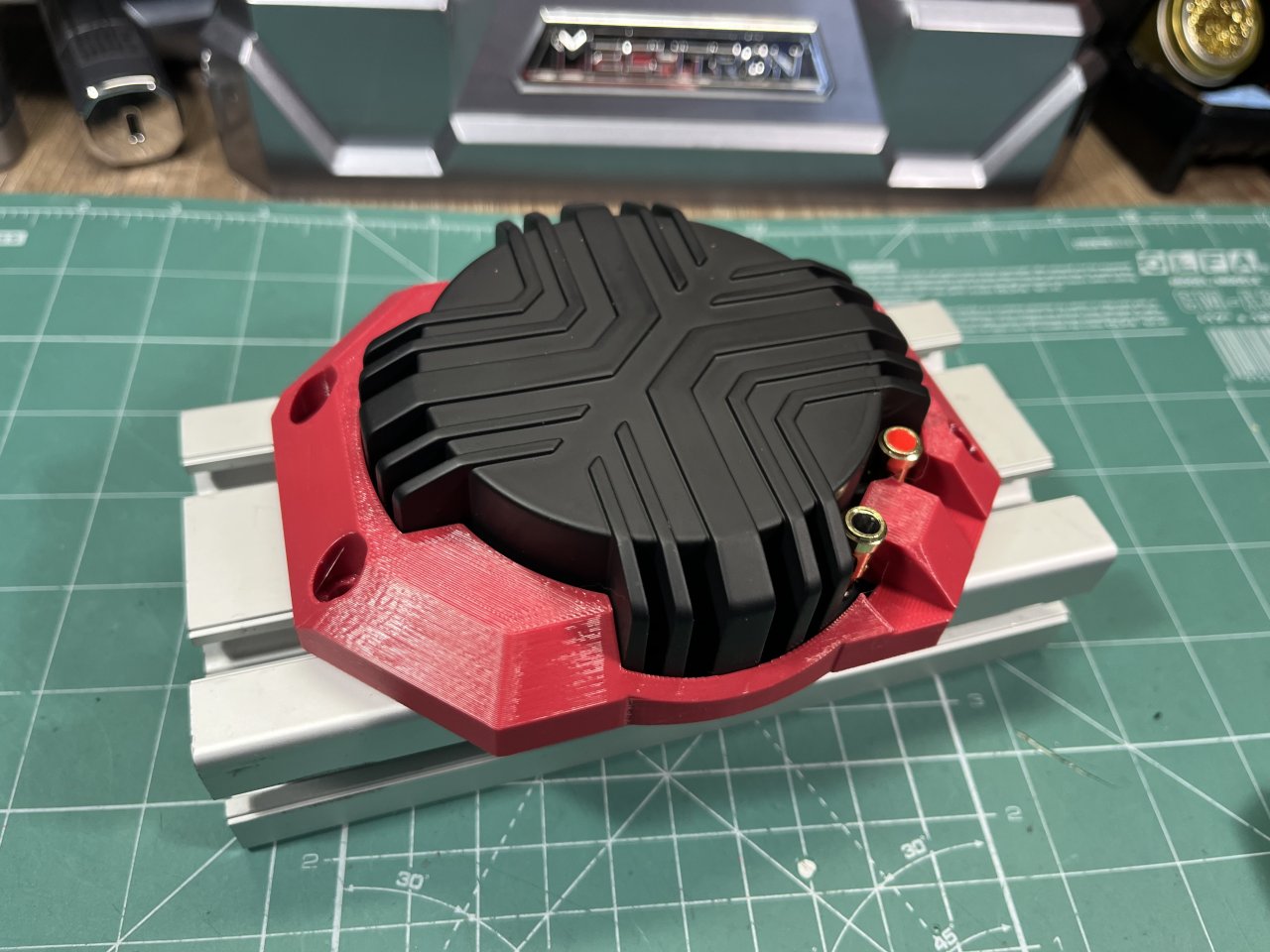

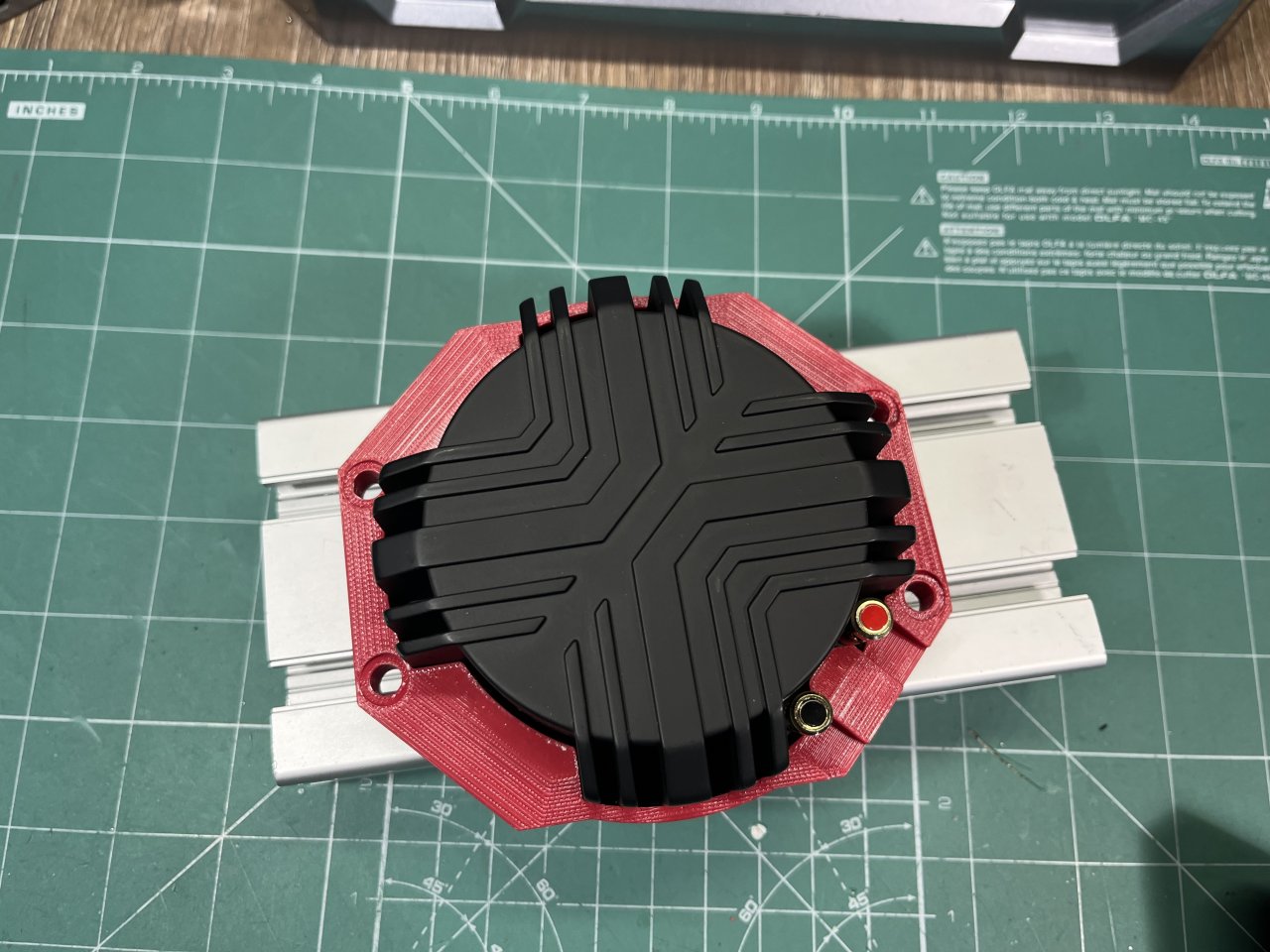

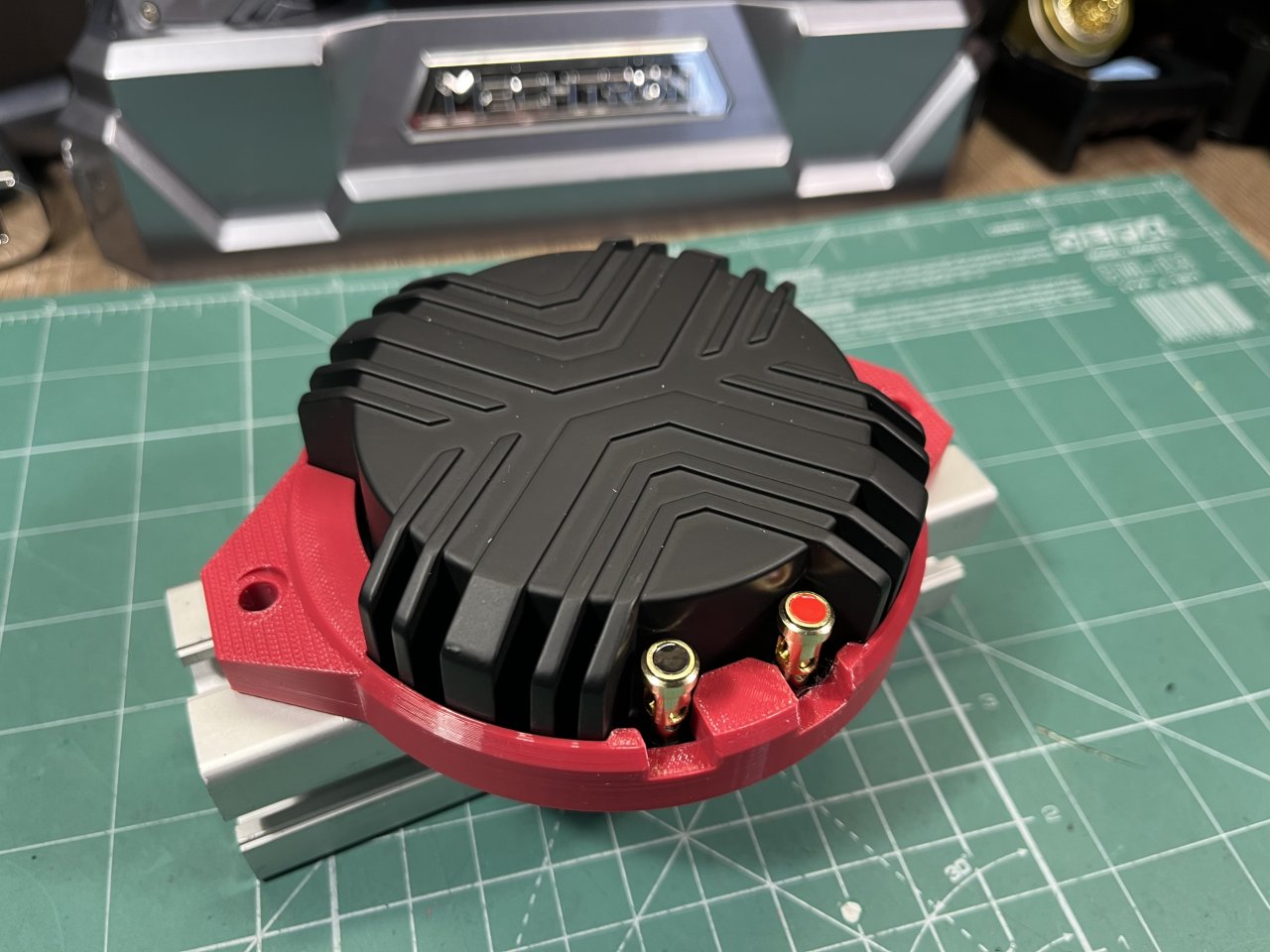

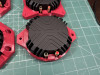

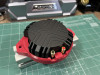

The new compact Xcite XBS50 bass shakers are great, but are not that easy to mount to alu extrusion profiles of a sim rig. Never fear, I is here!

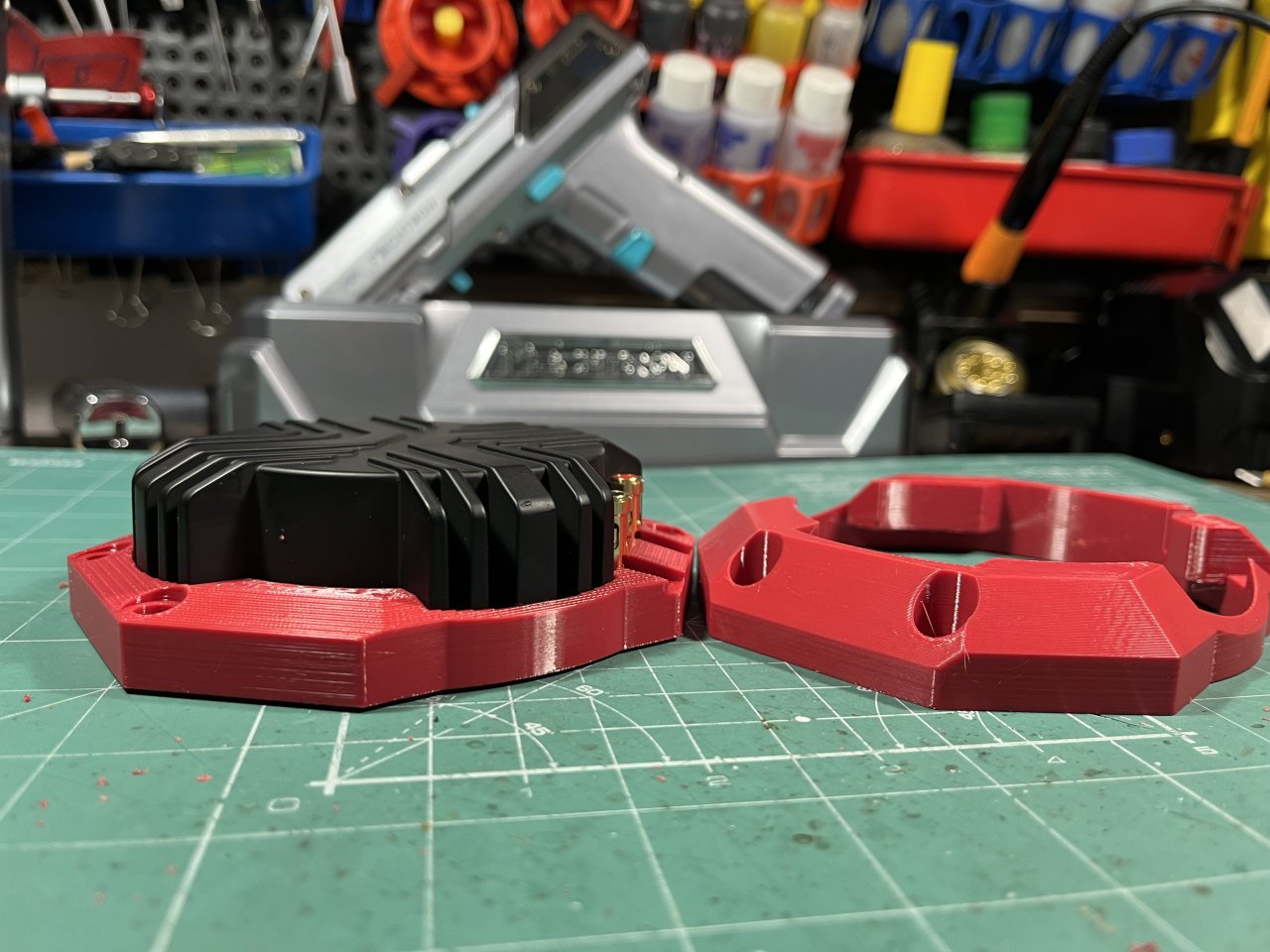

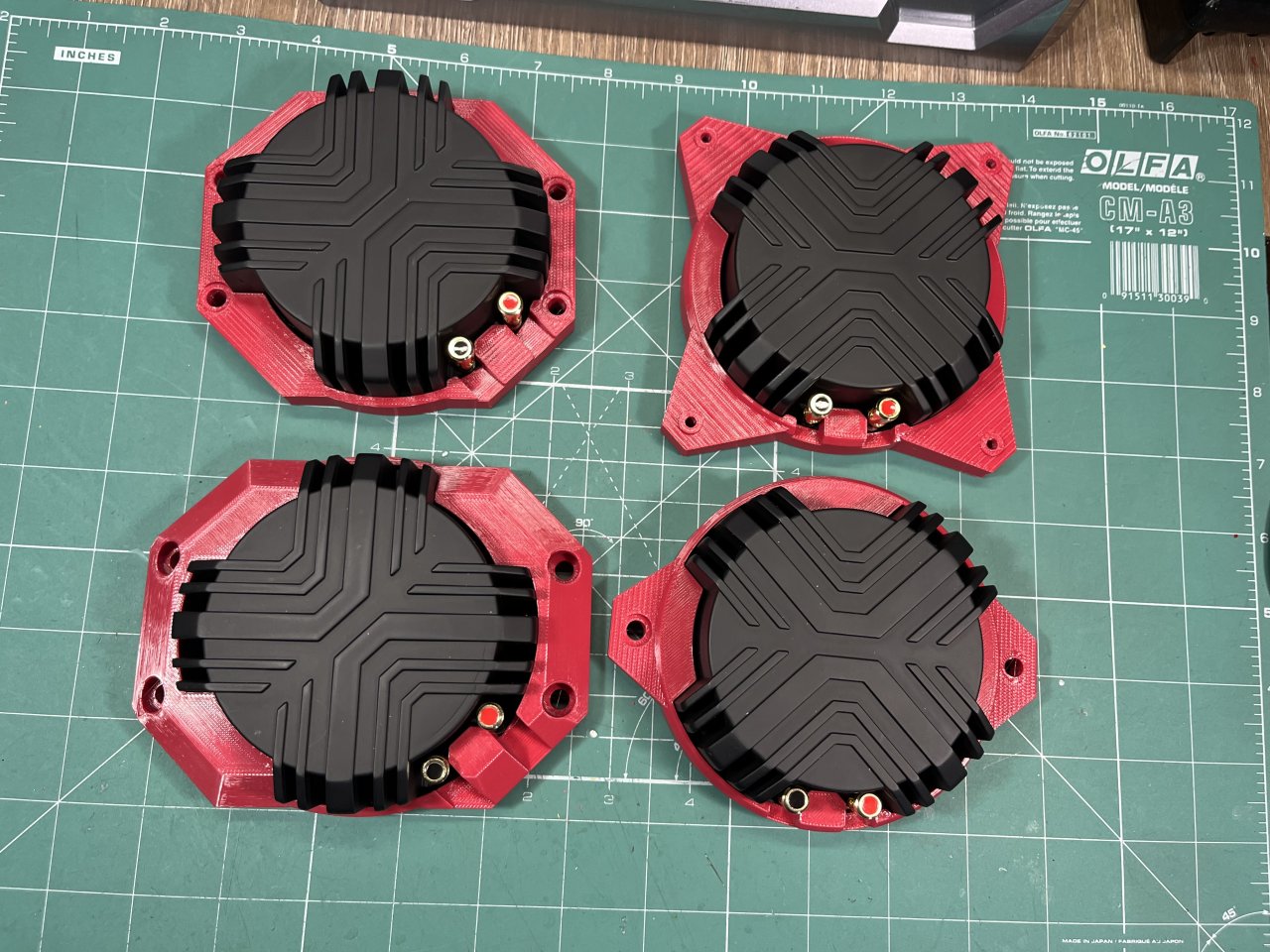

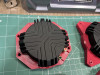

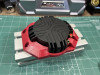

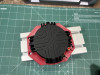

Designed simple mounts to solve this issue which simply slide on top of the device and press it against the surface below. The frames are intended to sandwich together and maintain structural integrity by using through bolts that keep the layers compressed.

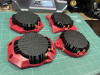

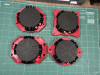

You will find the following variants in the kit:

1. Heavy Duty 8040 mount - has 4mm holes underneath that accept either M4 hardware or M3 brass heat insert - overkill in my opinion

2. Lite 8040 mount - slimmer version, only hardware needed is M6 socket bolts to mount to profile. Optimized for fast print and less material, works great

3. Low profile 4040 mount - very compact print, oriented in a way that mounting M6 bolts are quite near and have big contact area to press shaker next to profile

4. VESA 100 mount - drop in replacement to convert the new shaker to the 100mm standard used by my previous ones. Printed in PETG adds elasticity and is very comfortable to be mounted on curved surfaces, like my seat, for example.

5. Bonus: Offset 8040 Lite mount - designed to place the shaker aligned on one side with the 8040 profile edge, so it can be mounted on my shifter cluster under the TAU Sequential, which sits wider and gets in the way. Suitable if you do not have enough clearance to mount the shaker properly on the 8040 profile side.

All of the above, except the heavy duty one, have built in guide pins instead of relying on other hardware to mount together with shaker. They are aligned properly and fit great. In my opinion are not needed at all, but anyway added them just because I can!

-

Parts needed:

2. M6x14mm socket bolt and T-Slot nuts to mount to profiles

3. M4 bolts for the VESA 100 mount

4. M3/4 hardware if you really want them together with the heavy duty mount. For M3 you will need M3x6mm brass heat inserts

Print Settings:

Parts are to be printed in the orientation provided with support.

Recommended 6+ walls, 5 layers bottom/top and 25% Gyroid infill for dimensional stability

PETG works best as has good layer adhesion + elasticity and VESA mount can be used on slightly curved surfaces

Comments (0)